Technical Parameter of veneer patching machine (semi-automatic type)

Mending veneer size:≤2600*1270 mm for veneer peeled by 8ft/9ft rotary peeling machine,

Mending veneer thickness:0.5-6mm

Air pressure:0.6-0.95MPa

Entrance size of air:Φ12mm pipe

Patches mold size:100*60mm, 150*90mm, 250*120mm,350*50mm

Voltage:220V-50Hz

Line marking light power:3.5W*5

Valve:3W*4

Working table size:3000 *3355mm

Dimension:3600 *3355*1600mm

This technical parameter is for reference only, depend on veneer size, mold size and mold combination\

Features of veneer patching machine (semi-automatic type)

The edge of the punched patch is smooth and burr-free

Full pneumatic, high efficiency, durable, easy maintenance

Mold combination supports customization, convenient and flexible

There is a slight difference between the die size of the patch and the die size of the punching hole, which is easy to repair the adhesion.

Mould, no grinding for two years, no replacement for 10 years

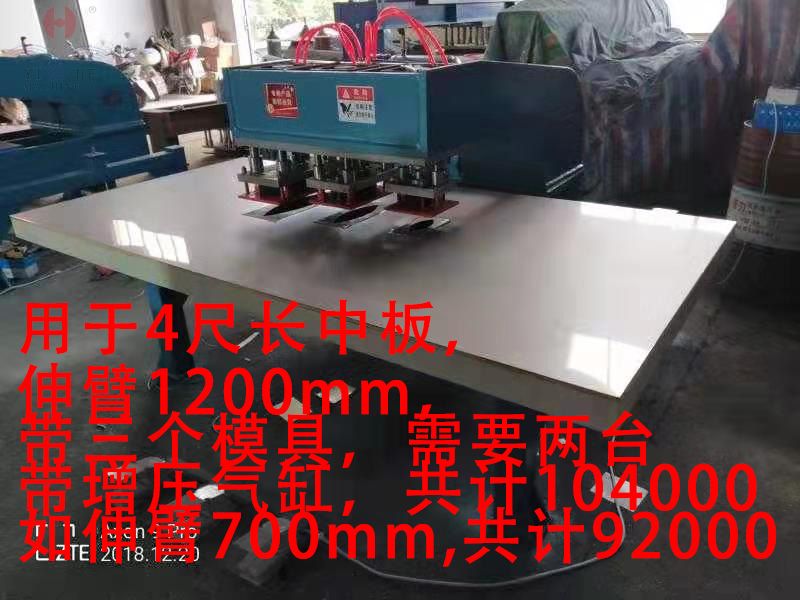

Pictures of veneer patching machine (semi-automatic type)